Temperature – What is it?

Temperature is one of the basic physical quantities (state parameters) in thermodynamics.

It is related to the average kinetic energy of motion and vibrations of all molecules forming a given system and is a measure of this energy. Temperature can be strictly defined only for thermodynamic equilibrium states, because from a thermodynamic point of view it is a quantity representing the shared property of two systems in equilibrium with each other.

Temperature is a measure of the thermal state of a given body. If the two bodies have the same temperature, they do not transmit heat in direct contact and when the temperature of both bodies is different, the heat from the body with a higher temperature to the lower body is passed – until the temperature of both bodies is evened out.

Sensors – What are they?

Sensor – a physical or biological component, which is most often a part of a larger system. It’s task is to capture signals from the surrounding environment, recognize and record them. In technical sciences, a sensor is a device that provides information about the appearance of a specific stimulus, exceeding a certain threshold value or the value of the registered physical quantity. In this approach, the sensor system consists of:

- Sensor,

- Converter,

- Signal conditioning system,

- Telemetry system.

The most common sensors are sensors that provide information in one of the electrical quantities, such as voltage, current, and electrical resistance. This is due to the fact that the electric current is a signal that can be easily amplified, sent over long distances, processed further using digital techniques and computers, and also kept. Temperature measurement and regulation is one of the most important activities in home applications. They are used in most electronic devices.

Temperature Sensors – Division

For the measurement of temperature, various types of sensors are commonly used, e.g. liquid, dilatative, bimetallic, manometric, semiconductor, thermoelectric, thermoresistive and other. In measuring systems in which the measured temperature is proportional to the electric current or voltage, thermoelectric and thermoresistive sensors are mainly used. The principle of operation of thermoelectric sensors is based on the Seebeck Effect. It creates an electromotive force “EMF” in an electric circuit composed of two different metals. It is proportional to the temperature difference between the measuring weld (connected ends of the thermocouple), which is affected by the measured temperature, and the reference temperature in which the unconnected, free ends of thermoelectrodes are located.

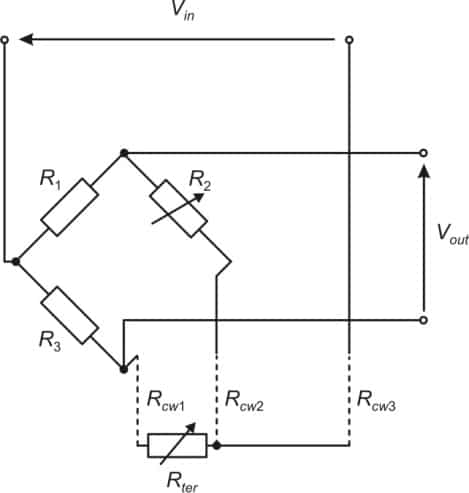

One of the correct operation conditions of thermoelectric sensors is the stability of the reference temperature. To ensure this, the so-called ”compensating wires” are used to extend the free ends of thermoelectrodes to a point of constant temperature (Fig. 1). These wires should be made of the same type of metals from which the sensor is made, because then no thermoelectric force is created at their connecting points. The use of other material for compensation pipes requires ensuring the same temperature at the place of their connection with the thermocouple.

Popular metals from which thermoelectric sensors are manufactured include the following pairs: iron-constantane, copper-constantane, copper-copper/nickel, nickel/chromium-nickel, nickel/chromium-constantan or platinum/rhodium-platinum, which are used in a very wide temperature range. It is worth noting that thermoelectric platinum/rhodium-platinum sensors have zero thermoelectric force between welds at 0° C.

The metal (e.g. copper, nickel, platinum) and semiconductor resistance dependence from temperature is used in resistance thermometers. In practice, the most popular thermoresistors have been metallic platinum, nickel, copper and semiconductor, so-called thermistors made of iron, manganese, nickel and lithium oxides, which are characterized by almost 10 times higher temperature coefficient than metallic thermoresistors. The disadvantage of semiconductor sensors is strongly non-linear characteristics and a large dispersion of parameters, which makes it difficult to compute them in measurement systems and is the cause of low repeatability of results.

Temperature Sensors – Where are they used?

In a household, home appliances using temperature sensors can be divided due to their size:

- Large appliances – washing machines, clothes dryers, dishwashers, refrigerators and freezers, ovens and stoves,

- Small appliances – coffee makers, induction hobs, irons and ice makers,

- Heating devices – heaters, radiators, fans and air conditioners.

Temperature Sensors – Environment of operation

In measurements, platinum thermoresistors are the most important due to the very stable parameters and the minimal non-linearity of the characteristic. For this reason, they are used as temperature standards. They are usually used up to 1000º C, because above this temperature, the platinum sublimates causing a change in the resistance of the wire. The upper limit of the applicability of nickel resistors is determined by the curvature of its temperature characteristics. This occurs at a temperature of about 300° C. Copper thermoresistors are not very resistant to oxidation and are used mainly in refrigeration and at temperatures close to ambient temperatures.

Thermoelectric sensors, especially in industrial measurements, must be protected against mechanical damage and chemically-active environment. Therefore, they are placed in tube-shaped covers with the head. These casings are usually made of cast iron, steel or heat-resistant alloys or ceramic materials and for obvious reasons they impair the dynamic properties of thermometers.

Let’s consider such properties for a thermometer with a single cover (Fig. 2.):

Temperature Sensors – Measuring systems

In measuring systems, thermometers work in bridges or semi-bridges configurations.

To balance the bridge before the measurements, an adjustable resistor “R2” is used. The resistor “Rter” changes its resistance depending on the temperature, causing the bridge to balance and the appearance of the voltage imbalance ”V”. This voltage can be fed to a current amplifier with adjustable gain, and then its output current for the measured temperature range should be within the rated range of 0-20 mA. This voltage can also be applied to the voltage amplifier and then its gain should be set in such a way that the output voltage for the measured temperature range is within the rated voltage range usually 0-10 V. Non-linear character of the system’s characteristic is most often software-corrected in a programmable amplifier cooperating with the output of the bridge.

In addition to bridge configurations, another often used method of temperature measurement is supplying thermoresistors directly from the current source. The voltage collected from “Rter” is then proportional to its value and the non-linearity of the temperature characteristic is as before frequently corrected with specialized software.