There are many types of wires that you can go with. Each of the wires has some advantages and disadvantages. We will see an overview of all the wires. This will give you a basic idea of all the wires. You can then decide which wire is for you.

Electrical wire

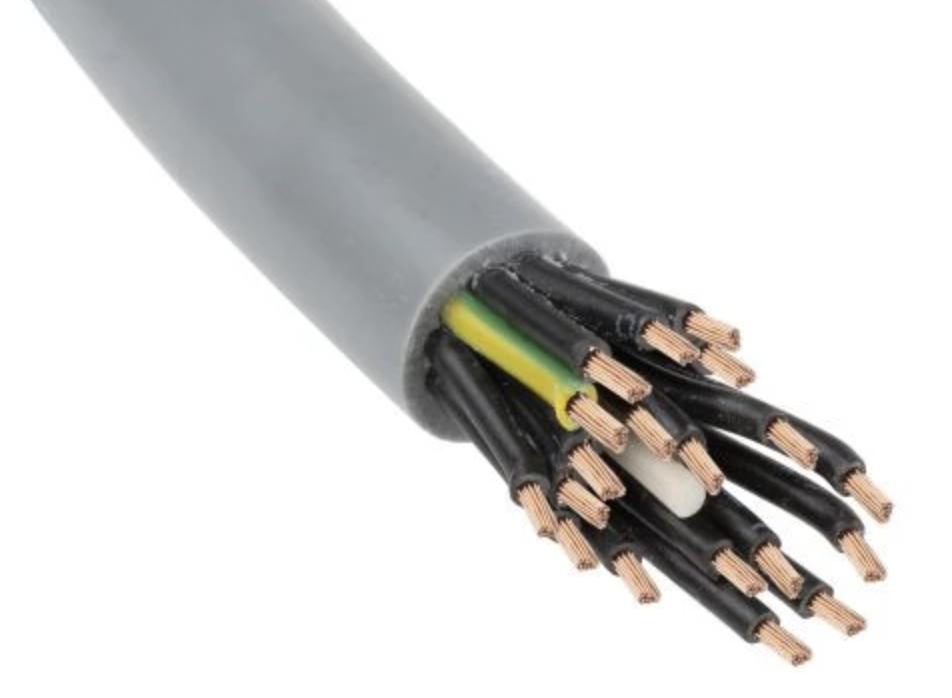

It’s one of the most common types of wires that you can go with. Electrical wire is the most common wire that you can use. Almost all the houses and offices use this type of wiring. These are the non-metallic or NM, cable. There are many names for the same type. Many people have the misconception that is cables and wires are the same things. However, they are not.

Electrical wires are any material that can conduct electricity. In simpler words, this is the wire that is wrapped with a rubber or any other insulator. There are also bare electrical wires which don’t have any of the jackets. There are three main types of wires. One of them is wires which are known as the neutral wire. The next is the black or red wire. These are the hot wires which will carry the current. The bare or the green wire is the ground wires.

Solar cable

As the name says, Solar cable is the cable that is used for photovoltaic power generation. This will use solar energy to transfer energy to the main hub. Usually, the solar wire is connected with the solar panels. The second end is connected with the electrical components or for a photovoltaic system. Solar wires are made keeping in mind the sunlight. So, it’s ultra-violet rays resistant as well as rain and weather resistant. The wires are kept in direct sunlight (usually on a terrace or open ground). Therefore, it needs to be weather resistant.

The solar cable can only be used where solar energy is used. Even if it has a large temperature, the wire can handle the temperature. There are electrical codes given by the national or local bodies. This will instruct you on how to install the wires on the panel. Depending on the country, the installation process might change. This is due to different temperatures in different cities and due to the different types of solar panels.

Teflon wire

Teflon wire is also known as PTFE wire. Usually, Teflon wire is used for the hook-up wire. So, you can also find the PTFE hook up wire. These are the wire that is a wrapper with the tape or other insulator. One of the unique things about Teflon wire is that it has a uniform thickness of the tape. The outer material is uniform to the conductor. Hookup wire is a family of wire which has a single conductor. For example, if there are more than two wires are wrapped together, it’s called a hookup wire.

PTFE stands for Polytetrafluoroethylene. It has many applications. One of the most common applications of PTFE hookup wire is the internal wiring. When there are high-frequency signals, PTFE wires are used as they can easily handle high frequency. The wires are usually non-stick and also includes heat resistant properties. PTFE hookup wire is available in many sizes. The size should depend on the number of wires you are using and the insulator thickness. Some people think Teflon and PTFE are different wires. However, they are almost the same thing. The only difference is in the name of the wire. Other than this, the material inside the wires is the same. This cable is safer and has better perfection. One of the Leading Chinese Cable Manufacturer can provide this type of wires as you will to order.

Welding cable

The next type of wire that you can use is welding cable. As the name says, it’s a wire that is used for welding. It’s an electrical conductor that carries the charge usually produced by an electric arc. In simpler words, it’s the charge produced by the reaction between the electrode and the metal. When the metal is welded, a charge is produced, regular wire can’t carry that charge. These wires are extremely flexible. You might have seen the person carrying the arc around the shop or the room. So, the wire needs to be flexible and also durable.

Talking about welding, there is a complete system. One of the welding cables will connect the machine and the electrode. Whereas, the second cable is used to connect the machine to the main hub or the electric station (work piece). In both places, welding wires are used to ensure safety and increase flexibility.

Battery cable

Battery cable is used along with any battery. The cables are generally for the automotive industry. Starting from small cars to huge road duty trucks, battery cable is very much useful. There is a cable needed that will carry the power from the battery to the transmitter or the engine. Here, a battery cable is used. The connection is from the battery to the ground (that is car frame). It’s copped wire which can easily handle a lot of heat. The car engine will surely catch the heat. So, the wire is capable of the same thing.

Along with this, it is also flexible and draws a high amount of current at the same time. Not just limited to the automobile battery, it is also used at many other places where the battery is needed. If it’s used for the heavy load vehicle or battery, there is an extra layer of protection. This will ensure safety against tears, abrasions, and many other machine parts. This is not mandatory but needed when there is heavy usage. So, this depends on the type of usage.

Final Words

To conclude, these are some of the most common types of wires that one can use for various reasons. Depending on the type of usage, you will need a different type of wire. So, you don’t have a choice on which wire to choose. Instead, it’s like a mandatory option. You will have to choose the one that fits with your requirements.